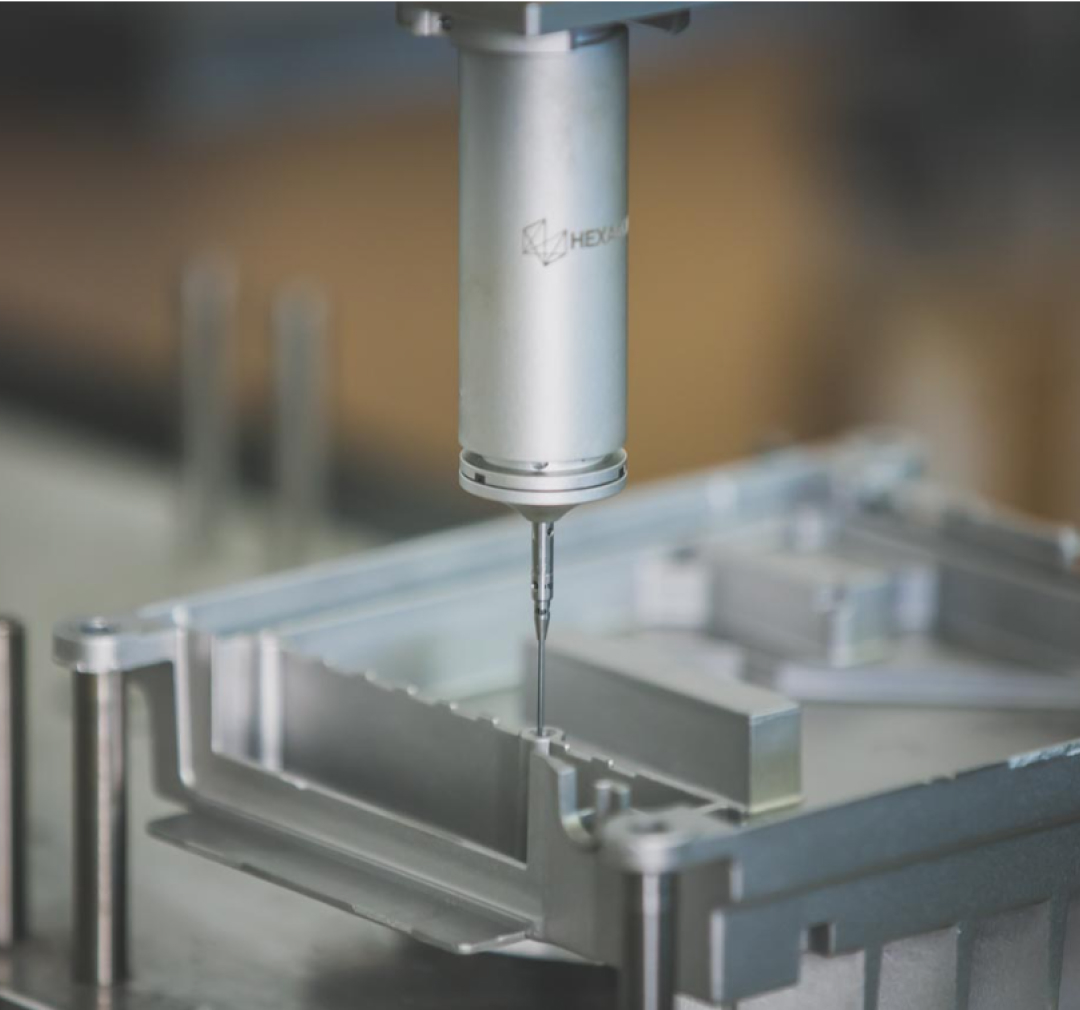

As part of the “Research–Create–Innovate” Action (Operational Program Competitiveness, Entrepreneurship and Innovation – EPAnEK – NSRF), the companies Rivimetal Ath. Rivios SA and Quintessential SFT IKE have undertaken the development of an innovative system for quality control of aluminum components, unprecedented in both Greek and international contexts.

This project aims to alleviate the problems of manual measurements and visual quality control. Innovative digital image processing is applied in order to check the components and measure the dimensions of 100% of the produced parts in real time.

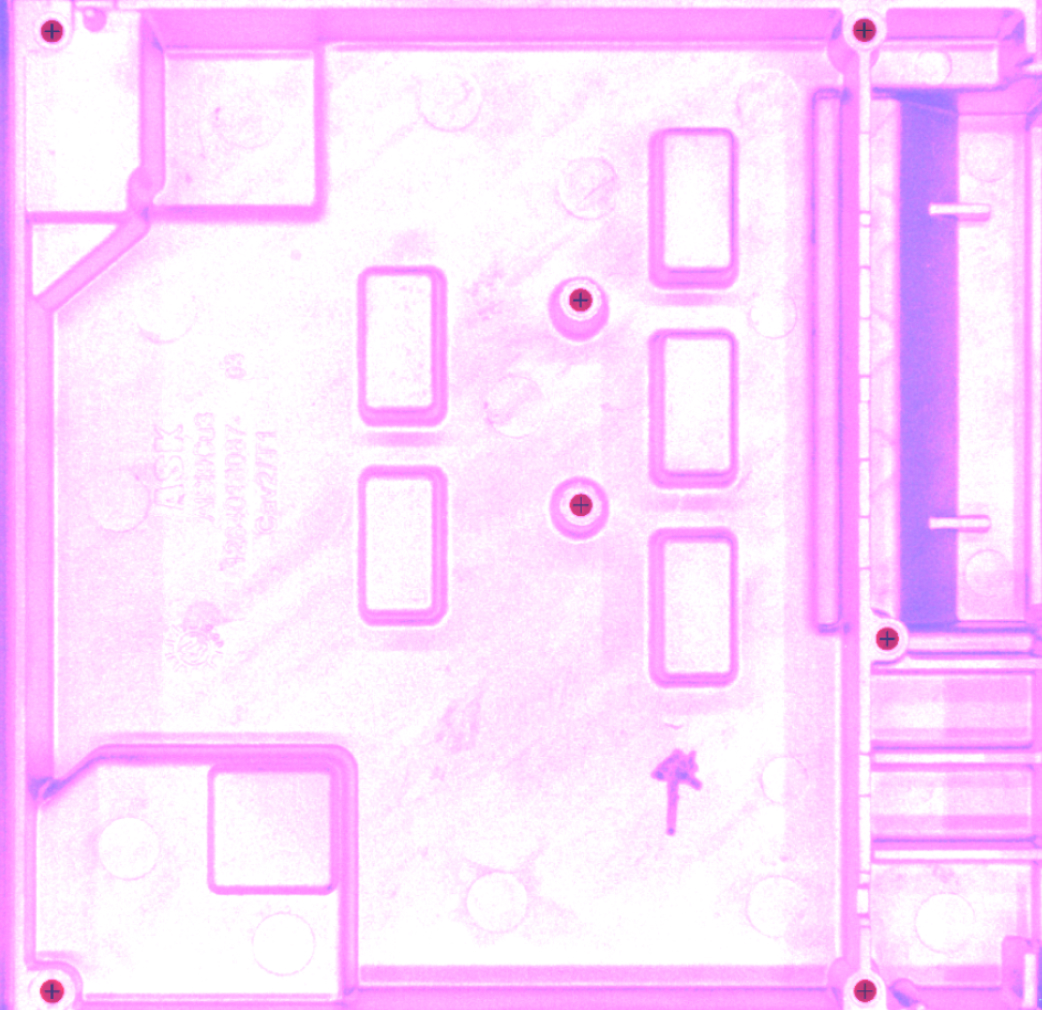

The application uses high-precision and high-definition cameras to digitally capture the part being examined. At the same time as the capture, computer vision and deep learning algorithms process the digital photograph at pixel and subpixel level. The algorithms measure the dimensions that have been determined while at the same detecting surface defects in the component.